The Hidden Costs of Waste in Factories

Waste is one of the most costly and underreported challenges facing modern factories. Whether it’s excess material use, energy inefficiencies, or prolonged downtime, waste can quietly erode profit margins and drag down operational efficiency. In today’s highly competitive manufacturing landscape, reducing waste isn’t just a “nice-to-have”—it’s essential for staying competitive and sustainable. PlantSharp MES is a solution designed to help factories tackle this issue head-on, transforming waste into opportunities for cost savings and efficiency gains.

The True Impact of Waste in Manufacturing

Waste takes many forms in a factory, and the financial impact can be staggering. Let’s break down some of the most common forms of waste that plague manufacturers:

- Material Waste: Excess use of raw materials or improper handling leads to unnecessary scrap and rework, driving up costs.

- Energy Inefficiencies: Running machines longer than necessary or at suboptimal settings not only wastes energy but also inflates utility bills.

- Downtime and Idle Time: Delays in production due to poor scheduling, equipment breakdowns, or waiting for materials reduce productivity and increase overhead costs.

- Overproduction: Producing more than current demand requires leads to inventory that costs money to store and manage.

Each of these issues cuts into your bottom line. Without a system that can identify and address these inefficiencies, factories often remain unaware of the scale of waste occurring every day.

How PlantSharp MES Addresses Waste in Factories

PlantSharp MES is designed to combat these inefficiencies by giving manufacturers the visibility and control they need to operate at maximum efficiency. Here’s how PlantSharp can help reduce waste and save your factory money:

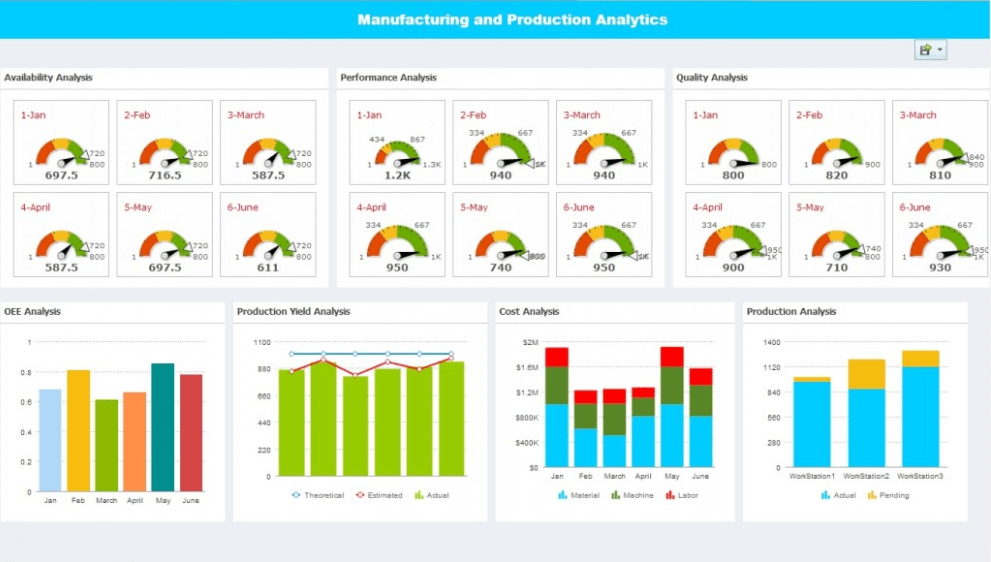

1. Real-Time Data for Better Decision-Making

In many factories, waste goes unnoticed simply because managers don’t have real-time insights into the production process. PlantSharp MES provides comprehensive, real-time data on every aspect of your operations. This allows managers to quickly spot where waste is occurring—whether it’s in material use, energy consumption, or idle machinery—and make immediate adjustments. The result? Less waste, more efficient production.

2. Optimized Material Use

Material waste is one of the biggest cost drivers in manufacturing. PlantSharp MES offers precise tracking of raw materials from the moment they enter the factory to the final product. By monitoring material use in real-time, PlantSharp helps you minimize excess usage and scrap, ensuring that every material is used as efficiently as possible.

3. Energy Efficiency through Automation

Energy costs can spiral out of control if machines are left running inefficiently or for longer than necessary. PlantSharp MES includes tools that monitor energy use and automatically adjust machine settings to optimize energy consumption. This not only reduces waste but also lowers your energy bills, helping your factory operate more sustainably.

4. Eliminate Downtime and Idle Time

Unplanned downtime is one of the biggest sources of lost productivity and waste in factories. PlantSharp MES uses advanced scheduling tools to ensure that every machine, operator, and material is aligned for optimal efficiency. By reducing downtime and keeping production flowing smoothly, your factory can increase output without incurring additional costs.

5. Control Overproduction and Inventory Costs

Overproduction is a common issue when manufacturing processes aren’t aligned with demand. PlantSharp MES integrates seamlessly with ERP systems to ensure that production is always matched to real-time demand forecasts. This prevents overproduction, reducing the need for costly inventory storage and management.

The Financial Impact of Waste Reduction

Reducing waste in your factory does more than improve operational efficiency—it also translates into significant financial savings. Here’s how PlantSharp MES can help boost your bottom line:

- Lower Material Costs: By cutting down on material waste, PlantSharp MES reduces the need for raw materials, saving you money over time.

- Reduced Energy Bills: Energy-efficient production reduces your factory’s overall energy consumption, leading to lower utility costs.

- Increased Productivity: With less downtime and better scheduling, your factory can produce more in less time, without the need for extra resources.

- Sustainability: Reducing waste not only saves money but also helps you meet sustainability goals, which can open up new market opportunities and enhance your brand’s reputation.

Why Choose PlantSharp MES?

PlantSharp MES isn’t just a software solution—it’s a strategic tool for driving waste reduction and operational excellence. By providing real-time insights, optimizing material and energy use, and improving scheduling, PlantSharp helps factories cut costs and boost efficiency. Whether you’re looking to reduce material waste, improve energy efficiency, or eliminate downtime, PlantSharp MES is the solution you need to transform your factory’s performance.

Ready to Reduce Waste and Increase Profits?

Don’t let waste quietly drain your profits. Discover how PlantSharp MES can help you tackle waste, improve efficiency, and save your factory significant money. Contact us today to schedule a demo and take the first step towards a leaner, more profitable future with PlantSharp.

By addressing the hidden costs of waste in factories, PlantSharp MES positions your business for long-term success in today’s competitive market.

We invite you to sign-up a Demo