Are you satisfied with your MES?

In today’s fast-paced manufacturing environment, a robust Manufacturing Execution System (MES) is crucial for operational efficiency. However, many manufacturers are discovering that their traditional MES systems are no longer meeting their evolving needs. These outdated MES solutions often struggle with scalability, fail to integrate real-time data, and feature rigid user interfaces that make adapting to new processes difficult. If your current MES system is hindering your operations, it may be time to consider an upgrade.

Why Traditional MES Systems Fall Short in Modern Manufacturing

Traditional Manufacturing Execution Systems were designed for static production environments. While they played a pivotal role in earlier manufacturing systems, they are no longer equipped to handle the dynamic, flexible, and fast-moving environments that are now the norm in the industry. These legacy systems often lack the necessary features for growth and efficiency in the modern world of manufacturing.

Key Issues with Traditional MES Systems:

-

Limited Integration: Many older MES solutions struggle to integrate seamlessly with new technologies like IoT devices, cloud computing, and modern ERP systems. This lack of integration often results in inefficient workflows and data silos, making decision-making slow and cumbersome.

-

Poor User Experience (UX): The interfaces of traditional MES systems are often outdated, leading to increased training times and higher chances of human error. The inability to adapt to user needs impacts operational efficiency and employee productivity.

-

Scalability Issues: As production needs grow, traditional MES systems often cannot scale efficiently, leading to performance bottlenecks and frequent costly system upgrades. A flexible and scalable MES solution is essential to keeping up with growing production lines and business demands.

How PlantSharp MES Solves These Problems

PlantSharp MES represents the next generation of Manufacturing Execution Systems, specifically designed to overcome the limitations of traditional MES systems and meet the demands of modern manufacturing. Here’s how PlantSharp stands out:

-

Seamless Integration with IoT & ERP Systems: PlantSharp’s advanced integration capabilities allow seamless connection with IoT devices, ERP systems, and cloud-based platforms. This ensures that all your data flows smoothly across the entire manufacturing process, promoting operational efficiency and reducing the risk of data silos.

-

User-Friendly Interface: Unlike outdated MES systems, PlantSharp MES offers a modern, intuitive user interface that employees can quickly adapt to. This dramatically reduces training time and minimizes user errors, leading to higher operational efficiency.

-

Scalable to Your Business Needs: Whether you’re adding new production lines, expanding facilities, or increasing production, PlantSharp MES grows with your business. Its scalability ensures that the system can handle increasing production demands without bottlenecks, resulting in continuous high performance.

-

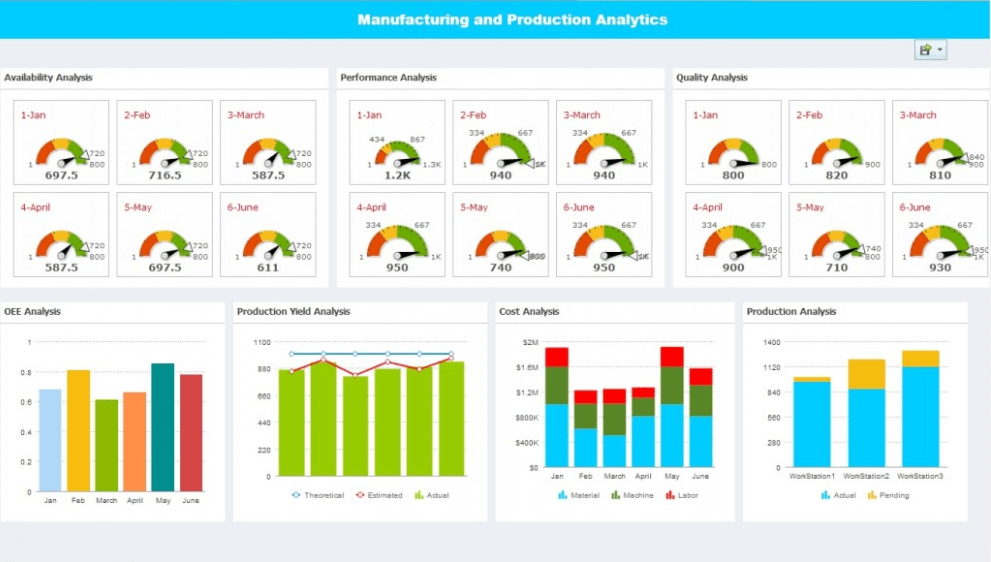

Real-Time Data Analytics: PlantSharp provides real-time data insights across all aspects of the production process, enabling immediate adjustments, informed decision-making, and faster reactions to operational challenges. This results in reduced downtime, improved throughput, and higher overall productivity.

-

Customization & Flexibility: PlantSharp is highly customizable to meet your specific manufacturing needs. This flexibility ensures the system adapts as your business evolves, helping you avoid the constraints that typically come with older MES systems.

Upgrade to PlantSharp MES for Increased Efficiency and Productivity

If your current MES system isn’t meeting your needs, it’s time to upgrade to PlantSharp MES. With its advanced integration, real-time analytics, intuitive interface, and scalability, PlantSharp MES transforms the way you manage production processes, offering enhanced visibility, efficiency, and adaptability.

Ready to Experience the Future of Manufacturing?

Sign up for a free demo and see firsthand how PlantSharp MES can optimize your operations. Discover the power of seamless integration and real-time data that will elevate your business to the next level in manufacturing. Don’t let your outdated MES system hold you back from success in the competitive manufacturing landscape.