How MES Gives You Bigger Bang for Your Buck

Manufacturing Execution Systems (MES) provides critical information that assists manufacturing decision makers to better understand how current conditions on the plant floor can be optimized to improve production output. A detailed ROI analysis requires identifying all benefits gained and costs incurred due to the MES implementation.

MES notoriously has been costly to implement with long execution schedules. However, with technological advances in smart devices and cloud-based systems, manufacturers can benefit from MES without substantial investments—costing less than a monthly luxury car payment.

This shift in productivity disrupts all three aspects—people, processes and systems—through the application of available technology. The catalyst for this improvement is access to data, and a lot of it, in a steady and consistent manner. The MES layer is intended to accumulate and provide this data.

The gaps in these scenarios exist in varying degrees across MES installations, and this is precisely where IIoT comes into play to expand the capabilities of MES rather than replace it. McKinsey & Company, a leading management consulting firm, has estimated that the economic impact of Internet of Things (IoT) will be $1.2 to $3.7 trillion by 2025. Gartner estimates that the number of connected IoT devices will rise well above 75 billion. Factories must implement smart solutions now if they want to reap these rewards and stay relevant. So why are so many manufacturers failing to implement solutions like MES into their operations?

ROI in Less Than 2 Months

Uncertainty Hinders Future Progress

According to a Gartner/MESA an International joint report, 63% of the companies surveyed stated that their biggest obstacle to implementing MES in their factories was that “cost, business case or Return on Investment (ROI) for the project was not properly understood.”

A recent report from Industry of Things World also confirmed this as a major initial challenge for smart factories. When asked what their biggest non-technical challenge to implementing IoT solutions is, 39% of ‘smart managers’ said “uncertain ROI and lack of business cases.”

The Diverse Benefits of MES

So now that we know that uncertain ROI is a major obstacle, let’s delve into what ROI actually is and how it’s normally calculated. A simple ROI calculation takes net profit from the investment divided by its cost. This calculation is sufficient for single-use and traditional investments that only deal in hard returns, but makes for a poor determination of ROI for modern, technological solutions that offer long-term benefits including both hard and soft returns.

Hard Returns of MES

Uncertainty Hinders Future Progress

According to a Gartner/MESA an International joint report, 63% of the companies surveyed stated that their biggest obstacle to implementing MES in their factories was that “cost, business case or Return on Investment (ROI) for the project was not properly understood.”

A recent report from Industry of Things World also confirmed this as a major initial challenge for smart factories. When asked what their biggest non-technical challenge to implementing IoT solutions is, 39% of ‘smart managers’ said “uncertain ROI and lack of business cases.”

The Diverse Benefits of MES

So now that we know that uncertain ROI is a major obstacle, let’s delve into what ROI actually is and how it’s normally calculated. A simple ROI calculation takes net profit from the investment divided by its cost. This calculation is sufficient for single-use and traditional investments that only deal in hard returns, but makes for a poor determination of ROI for modern, technological solutions that offer long-term benefits including both hard and soft returns.

Hard Returns of MES

Uncertainty Hinders Future Progress

According to a Gartner/MESA an International joint report, 63% of the companies surveyed stated that their biggest obstacle to implementing MES in their factories was that “cost, business case or Return on Investment (ROI) for the project was not properly understood.”

A recent report from Industry of Things World also confirmed this as a major initial challenge for smart factories. When asked what their biggest non-technical challenge to implementing IoT solutions is, 39% of ‘smart managers’ said “uncertain ROI and lack of business cases.”

The Diverse Benefits of MES

So now that we know that uncertain ROI is a major obstacle, let’s delve into what ROI actually is and how it’s normally calculated. A simple ROI calculation takes net profit from the investment divided by its cost. This calculation is sufficient for single-use and traditional investments that only deal in hard returns, but makes for a poor determination of ROI for modern, technological solutions that offer long-term benefits including both hard and soft returns.

Hard Returns of MES

Uncertainty Hinders Future Progress

According to a Gartner/MESA an International joint report, 63% of the companies surveyed stated that their biggest obstacle to implementing MES in their factories was that “cost, business case or Return on Investment (ROI) for the project was not properly understood.”

A recent report from Industry of Things World also confirmed this as a major initial challenge for smart factories. When asked what their biggest non-technical challenge to implementing IoT solutions is, 39% of ‘smart managers’ said “uncertain ROI and lack of business cases.”

The Diverse Benefits of MES

So now that we know that uncertain ROI is a major obstacle, let’s delve into what ROI actually is and how it’s normally calculated. A simple ROI calculation takes net profit from the investment divided by its cost. This calculation is sufficient for single-use and traditional investments that only deal in hard returns, but makes for a poor determination of ROI for modern, technological solutions that offer long-term benefits including both hard and soft returns.

Hard Returns of MES

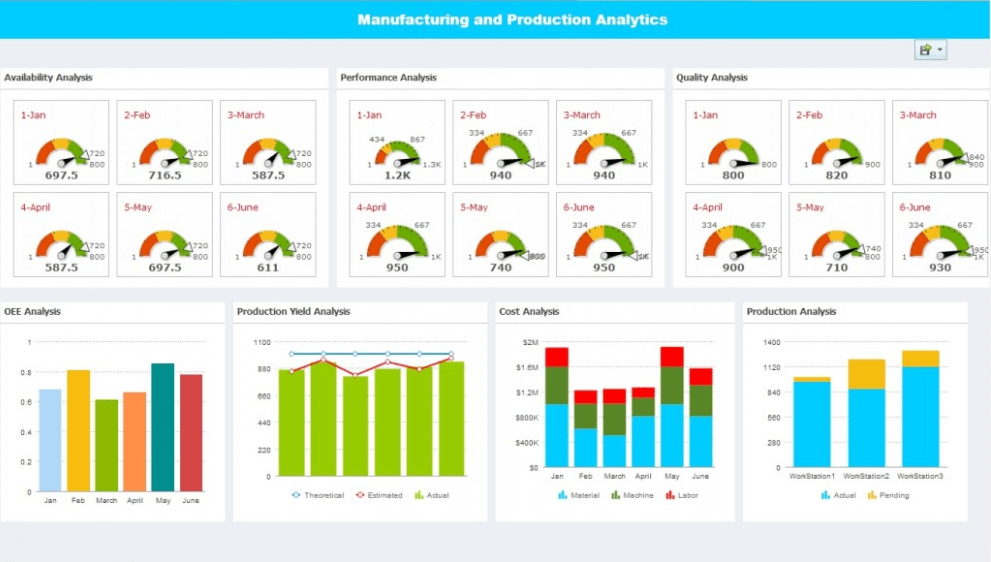

- Increased productivity and OEE – Trunovate’s customers see significant gains between 2 to 6 months of implementing MES solutions. Our customers see an annual increase in overall equipment effectiveness (OEE) starting at 8% after implementing our MES solutions, PlantSharp 4.0.

- Reduced waste and loss of materials – Our experience has shown that implementing MES enables a 24% reduction in unnecessary inventory. That’s nearly a quarter of stock that may be going to waste, causing a huge drop in profits!

- Reduced human error rate and manual data collection – After implementing PlantSharp 4.0, our clients see their factory floor automated by over 90%, leading to a massive reduction in the human error factor and lower defect rate.

- Improved and increased quality – Trunovate customers see a 10% improvement in quality/yield after incorporating MES solutions. With the rise of Machine Learning and AI, this number will increase even further and companies will get closer to achieving their Golden Batch every time.

- Wiser, quicker decision-making – MES solutions provide crucial insights into your operations, collected from your plant’s machine data. With this knowledge, managers and operators can make quicker, smarter decisions that will contribute to hard benefits in the future.

- Optimization leads to more innovation – Knowledge gained from massive amounts of factory data along with the time-saving and productivity benefits of MES enables manufacturers and workers to focus their energy on new plans and projects.

- Standardized processes gets everyone on the same page – MES allows the entire factory to see the production process on the same screen. This enables real-time resource sharing, problem-solving and creates a better, more flexible work environment for all supervisors and operators.

Tagged iiot, MES, ROI, Smart Manufacturing, Trunovate