Embracing the Transition from Industry 4.0 to Industry 5.0

The Manufacturing Industry’s Transformation: From Industry 4.0 to 5.0

The manufacturing industry is undergoing a significant transformation, fueled by the digitization and automation of processes ushered in by Industry 4.0. This fourth industrial revolution has reshaped production through the integration of cyber-physical systems, Internet of Things (IoT), and artificial intelligence (AI). However, as the capabilities of Industry 4.0 continue to evolve, we’re now entering the next phase: Industry 5.0.

The Evolution from Industry 4.0 to Industry 5.0

While Industry 4.0 focused on process automation and optimization via advanced technologies, Industry 5.0 takes a step further by emphasizing human-machine collaboration. This transition seeks to enhance the human aspect of manufacturing, ensuring that technology complements and augments human skills instead of replacing them.

Preparing for the Shift to Industry 5.0 with PlantSharp MES

To make the transition from Industry 4.0 to Industry 5.0 seamless, manufacturers must adopt a comprehensive approach. This approach should include investing in advanced technologies like PlantSharp MES, training their workforce, and embracing sustainability practices. By focusing on innovation, workforce development, and human-centric manufacturing, businesses can ensure a successful future in the evolving industrial landscape.

Key Steps to Transition to Industry 5.0:

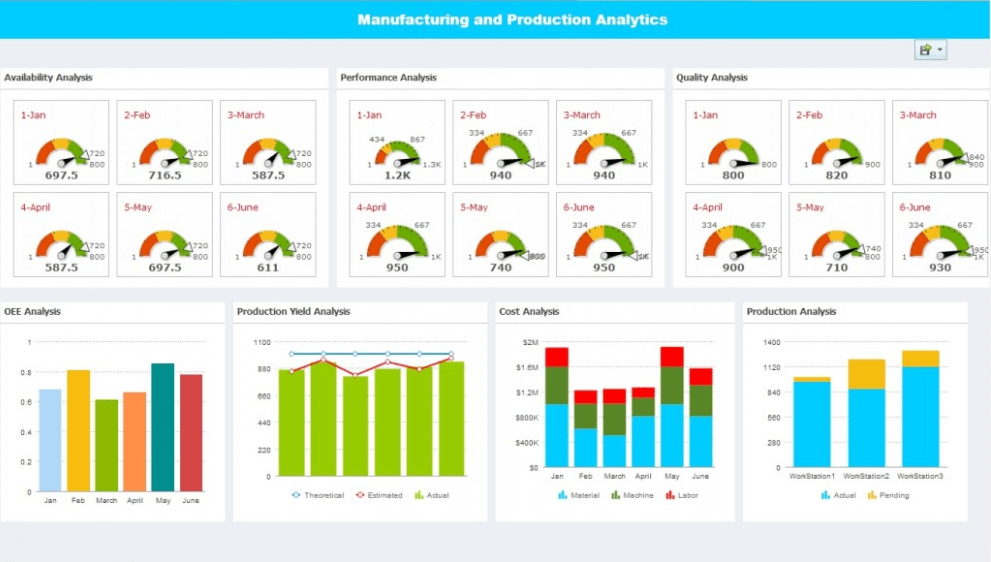

Invest in Advanced Technologies with PlantSharp MES

Leverage PlantSharp MES to enable human-machine collaboration. This solution allows for easy, quick setup of MES systems on the shop floor, with the flexibility to customize for each factory and industry’s needs.Upskill the Workforce

Provide training and development programs that prepare employees to work alongside advanced technologies. PlantSharp MES offers self-service software, enabling employees to handle strategic roles and contribute to operational improvements.Adopt Sustainable Manufacturing Practices

Implement eco-friendly processes and prioritize sustainability throughout production. PlantSharp MES integrates AI, Energy, Maintenance, Quality, WIP, and Scale add-ons that drive sustainability in production, meeting both environmental and business goals.

The Benefits of Industry 5.0:

Enhanced Innovation

Human creativity combined with machine efficiency will foster groundbreaking solutions and innovative products. The collaborative aspect of Industry 5.0 unlocks new opportunities for businesses to evolve.Improved Employee Satisfaction

By automating mundane tasks, Industry 5.0 allows employees to focus on more meaningful roles. This shift leads to higher job satisfaction and employee retention, fostering a positive workplace culture.Greater Flexibility and Agility

Industry 5.0 enables rapid adaptation to changing market conditions and consumer demands. The ability to produce customized products on demand ensures a competitive edge in the global market, providing flexibility to meet evolving customer preferences.

Conclusion: Embrace the Future with PlantSharp MES

As we transition from Industry 4.0 to Industry 5.0, the manufacturing industry is set for another wave of transformative change. By combining human ingenuity with machine precision, Industry 5.0 will drive innovation, customization, and sustainability. Embrace PlantSharp MES to build a resilient, agile manufacturing environment that ensures your business remains competitive in the fast-evolving market landscape.