How to Know If Your Shop Floor Is Ready for MES Implementation?

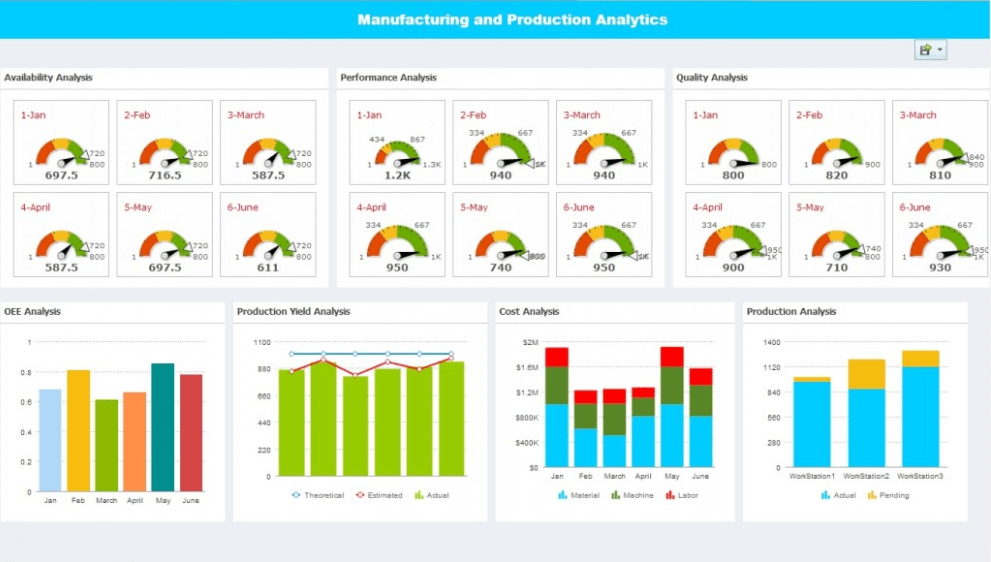

The PlantSharp MES (Manufacturing Execution System) offers an advanced software solution for managing, controlling, and optimizing production processes. Successful implementation of PlantSharp MES can lead to significant improvements in productivity, product quality, operational efficiency, and production costs. However, not every shop floor is ready for MES implementation. Here are some key points for self-assessment:

1. Process Governance:

Successful implementation of PlantSharp MES requires knowing the manufacturing governance of the production processes. Map out the sequence of operations at each production stage, from raw material intake to the finished product and simple configure the processes into PlantSharp MES.

2. Available Data:

PlantSharp MES relies on real-time data. Therefore, it is essential to ensure you have the appropriate infrastructure for collecting data from the shop floor, such as control systems (PLCs) and sensors. This data will enable MES to track production progress, identify bottlenecks, and optimize processes.

3. Communication Infrastructure:

Reliable communication between PlantSharp MES and other organizational systems, such as Enterprise Resource Planning (ERP) systems and control systems, is important for achieving a holistic view of production processes. Ensure you have a dependable communication network that allows continuous data transfer.

4. Skilled Personnel:

Implementing PlantSharp MES requires the cooperation of your workforce. Operators will need to learn how to work with the new system and maximize its benefits. Additionally, it is important to have a designated person within the plant to support the team during the initial stages of using the MES system. We recommend to use Triple O’s adoption plan to achieve successful implementation.

5. Management Commitment:

The success of PlantSharp MES implementation largely depends on management’s commitment. Through production management, production costs can be reduced and ROI from lines and machines can be increased. Therefore, active support from management is crucial, both in terms of allocating necessary resources and encouraging employee cooperation.

Conclusion:

Successful implementation of PlantSharp MES on the shop floor can be easily achieved by the plant. By documenting processes, collecting data, ensuring proper communication infrastructure, having a skilled workforce, and receiving managerial support, you can create the ideal foundation for successful MES implementation and lead your plant to significant performance improvements.

Implementing these steps will help ensure your shop floor is ready for the benefits that PlantSharp MES can offer, paving the way for enhanced efficiency, cost savings, and improved overall production quality. Read more in our website www.trunovate.com