Leveraging data for optimal maintenance & product quality

Producing high quality products at minimal cost is a timeless manufacturing goal. Industry 4.0 is already demonstrating its value by enabling manufacturers to achieve their ‘Golden Batch’. The core technologies driving this new wave of ultra-automation are Industrial AI and Machine Learning. Data has become a valuable resource for manufacturing plants. Through the use of artificial intelligence, specifically process-based machine learning, manufacturers can use data to significantly impact their bottom line by greatly improving production efficiency, product quality, and employee safety. While certain manufacturers do perform Predictive Maintenance, it has traditionally been done using SCADA systems set up with human-coded thresholds, alert rules and configurations. This semi-manual approach doesn’t take into account the more complex dynamic behavioral patterns of the machinery, or the contextual data relating to the manufacturing process at large. For example, a sensor on a production machine may pick up a sudden rise in temperature. A static rule-based system would not take into account the fact that the machine is undergoing sterilization and would proceed to trigger a false-positive alert. In contrast, Machine Learning algorithms are fed operational technology data (from the production floor: sensors and SCADA), IT data (contextual data: ERP, quality, MES, etc.), and manufacturing process information describing the synchronicity between the machines and the rate of production flow. In industrial AI, algorithms can easily detect anomalies and test correlations while searching for patterns across the various data feeds. The power of Machine Learning lies in its capacity to analyze very large amounts of data in real time and propose actionable responses to issues that may arise.The Benefits of Machine Learning and AI for Manufacturing

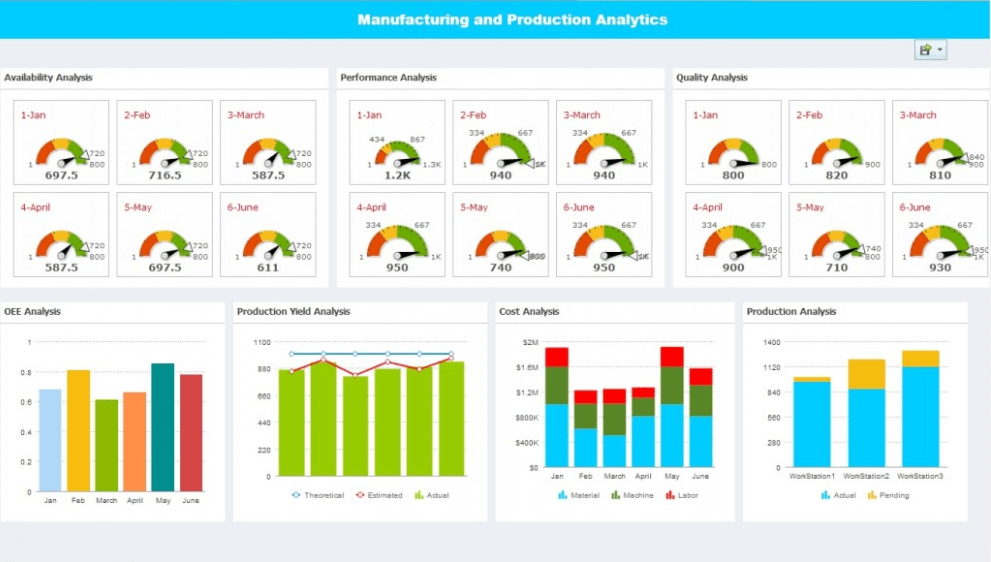

AI and Machine Learning introduce a sea of change that provide many benefits that can result in advantages well beyond efficiency improvements, opening doors to new business opportunities. Some of the direct benefits of Machine Learning in manufacturing include:- Cost reduction through QA Predictive Maintenance, leading to less maintenance activity, which means lower labor costs and reduced inventory and materials wastage.

- Knowing more about the behavior of machines and equipment leads to creating conditions that improve performance while maintaining machine health.

- Assisting in being more aware of “unpleasant surprises” that cause unplanned downtime.

- Improved supply chain management through efficient inventory management and a well monitored and synchronized production flow.

- Improved Quality Control with actionable insights to constantly raise product quality.

- Improved Human-Robot collaboration improving employee safety conditions and boosting overall efficiency.

- Consumer-focused manufacturing – being able to respond quickly to changes in the market demand.