Tips for Factory Maintenance Managers:

Preventive Maintenance:

- Define a Preventive Maintenance Plan: Create a regular schedule for inspecting and repairing equipment, machines, and production lines.

- Use Monitoring Systems: Install monitoring systems that alert you to potential issues before they become major problems.

- Manage Spare Parts Inventory: Ensure you have all necessary spare parts on hand to avoid delays in repairs.

- Train Your Maintenance Team: Make sure your maintenance staff is properly trained in using the equipment and machines.

Efficient Management:

- Use a Computerized Management System: A computerized system can help you track maintenance data, manage teams, and prioritize repairs.

- Improve Communication: Ensure there is good communication between maintenance, production, and management teams.

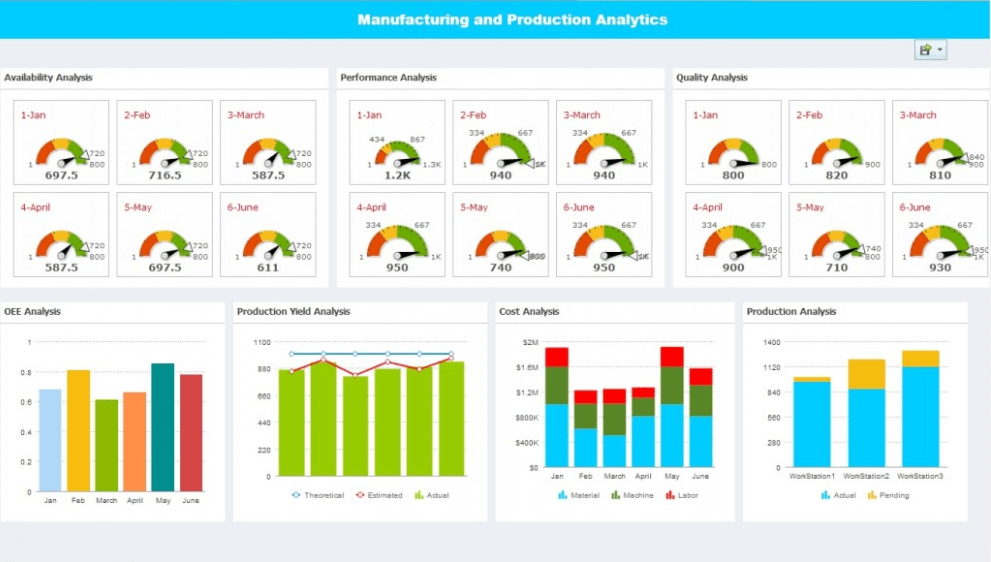

- Analyze Data: Track maintenance data to identify patterns and improve work processes.

- Be Proactive: Don’t wait for a breakdown to act. Be proactive in identifying and addressing potential issues.

Impact of Maintenance on Productivity and Quality:

- Good Maintenance Can Reduce Downtime: Poorly functioning equipment and machines cause downtime, reducing productivity. Good maintenance can help prevent shutdowns and keep production lines running.

- Good Maintenance Can Improve Product Quality: Poorly maintained equipment and machines can produce defective products. Good maintenance can help improve product quality and reduce waste.

- Good Maintenance Can Enhance Safety: Poorly maintained equipment and machines can be dangerous. Good maintenance can help prevent accidents and keep workers safe.

- Good Maintenance Can Save Money: Repair and preventive maintenance costs are much lower than the costs of replacing equipment and machines. Good maintenance can help you save money in the long run.

Implementing these tips can significantly improve the efficiency and effectiveness of your maintenance operations, leading to increased productivity, better product quality, enhanced safety, and cost savings.

By using Maintenance Add-on of PlantSharp MES you can simplify maintenance processes and management in correlation to production data for detailed plant view. Read more in our site Trunovate.com/Maintenance