We’re in the midst of a significant transformation regarding the way we produce products thanks to the digitization of manufacturing. This compelling transition is called Industry 4.0 – which is a representation of the fourth revolution that has occurred in manufacturing. Like the three industrial revolutions which preceded it – steam power, mass production/electricity, digital age – Industry 4.0 will transform local and global economies and create a new future for us all.

Industry 4.0 Applications Today

While many organizations might still be in denial about Industry 4.0 and how it can impact their operations, many others have already started implementation and preparing for the future so that smart machines can improve their business.

Here are a Few Possible Applications

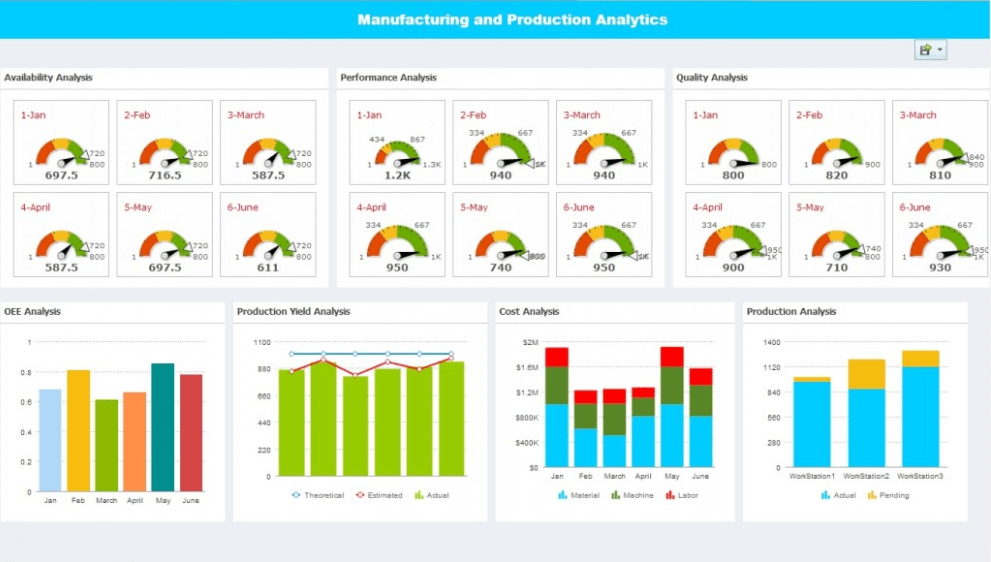

Connected machines collect a tremendous volume of data that can inform quality performance and many other issues as well as analyze data to identify patterns and insights that would be impossible for a human to do in a reasonable timeframe. Industry 4.0 gives manufacturers the ability for quick optimization, allowing efficiency by knowing what needs attention. By using data from sensors in its equipment, an African gold mine identified problems with the oxygen levels during leaching. Once fixed they were able to increase their yield by 3.7%, which saved them $20 million annually, according to McKinsey & Company.

Taking Industry 4.0 to a Whole New Level

Let’s take a watch for example: Before IoT, a watch was just a simple device that told time. Now we have smart watches, like the Apple Watch, that are connected to the Internet and have multiple sensors, tracking fitness and collecting other health-oriented data for us to use. IoT is redefining how people interact with objects and how they manage day-to-day tasks.

Industry 4.0 takes this concept to a whole new level – the Industrial Internet of Things (IIoT) and cyber-physical systems. Connecting the factory floor to IIoT software allows humans and machines to communicate with one another and work as one unified team. With Industry 4.0 manufacturers can gather real-time data from all parts of the manufacturing process so decisions can be made quickly and efficiently; and automate and streamline processes, reducing waste and increasing productivity and Overall Equipment Effectiveness (OEE).

The massive amount of accurate data that is obtained in real time from IIoT-outfitted machinery creates an evidence-based environment, allowing manufacturers to make informed decisions more confidently and quickly.

These insights are paramount to successful manufacturing in a global economy. Tracking production from start to finish ensures that all raw materials and finished goods meet regulatory standards and are of the highest quality. If a problem arises, the source can be discovered in near real-time, reducing material waste and the risk of catastrophic recalls.

Adding Machine Learning and Artificial Intelligence to the Mix

Predictive analytics, machine learning and artificial intelligence (AI) are also changing how many businesses and industries operate, including manufacturing. By using machine learning techniques and AI, developers can create prediction models based on data from systems with IIoT.

Algorithmic solutions can benefit manufacturers by predicting the quality of their finished goods at the start of the production process, in order to increase the chances of producing a Golden Batch EVERY time.

Data can be analyzed to predict how well machinery is running at all times. Problems with machinery can then be detected and fixed much faster, leading to fewer stoppages and increased output. The activities of the operators and supervisors on each production line can also be taken into account, their output measured and predicted, leading to increased productivity and a more efficient factory floor.

Founder Institute

Founder Institute

Industry 4.0 Applications Today

While many organizations might still be in denial about Industry 4.0 and how it can impact their operations, many others have already started implementation and preparing for the future so that smart machines can improve their business.

Here are a Few Possible Applications

Connected machines collect a tremendous volume of data that can inform quality performance and many other issues as well as analyze data to identify patterns and insights that would be impossible for a human to do in a reasonable timeframe. Industry 4.0 gives manufacturers the ability for quick optimization, allowing efficiency by knowing what needs attention. By using data from sensors in its equipment, an African gold mine identified problems with the oxygen levels during leaching. Once fixed they were able to increase their yield by 3.7%, which saved them $20 million annually, according to McKinsey & Company.

Taking Industry 4.0 to a Whole New Level

Let’s take a watch for example: Before IoT, a watch was just a simple device that told time. Now we have smart watches, like the Apple Watch, that are connected to the Internet and have multiple sensors, tracking fitness and collecting other health-oriented data for us to use. IoT is redefining how people interact with objects and how they manage day-to-day tasks.

Industry 4.0 takes this concept to a whole new level – the Industrial Internet of Things (IIoT) and cyber-physical systems. Connecting the factory floor to IIoT software allows humans and machines to communicate with one another and work as one unified team. With Industry 4.0 manufacturers can gather real-time data from all parts of the manufacturing process so decisions can be made quickly and efficiently; and automate and streamline processes, reducing waste and increasing productivity and Overall Equipment Effectiveness (OEE).

The massive amount of accurate data that is obtained in real time from IIoT-outfitted machinery creates an evidence-based environment, allowing manufacturers to make informed decisions more confidently and quickly.

These insights are paramount to successful manufacturing in a global economy. Tracking production from start to finish ensures that all raw materials and finished goods meet regulatory standards and are of the highest quality. If a problem arises, the source can be discovered in near real-time, reducing material waste and the risk of catastrophic recalls.

Adding Machine Learning and Artificial Intelligence to the Mix

Predictive analytics, machine learning and artificial intelligence (AI) are also changing how many businesses and industries operate, including manufacturing. By using machine learning techniques and AI, developers can create prediction models based on data from systems with IIoT.

Algorithmic solutions can benefit manufacturers by predicting the quality of their finished goods at the start of the production process, in order to increase the chances of producing a Golden Batch EVERY time.

Data can be analyzed to predict how well machinery is running at all times. Problems with machinery can then be detected and fixed much faster, leading to fewer stoppages and increased output. The activities of the operators and supervisors on each production line can also be taken into account, their output measured and predicted, leading to increased productivity and a more efficient factory floor.

Becoming an Industry 4.0 Manufacturer

“Swiss giant ABB used the latter in an Australian cement kiln. A computer-based system mimics the actions of an “ideal” operator, using real-time metrics to adjust kiln feed, fuel flow, and fan-damper position. The company found that the new tools boosted throughput by up to 5 percent.” – McKinsey & Company

Keeping up with the fast-paced, revolutionary world of Industry 4.0, IIoT, and smart factories is imperative for today’s manufacturers if manufacturer owners want to become tomorrow’s industry leaders.Contact Trunovate to implement PlantSharp4, our unique Industry 4.0 solution.