Manufacturing has experienced a series of revolutionary technological advancements in the past several years that is impacting every facet of the factory floor. Manufacturers must invest in smart solutions and optimize their operations if they want to be industry leaders in a world where the relationship between humans and machines grows stronger by the nanosecond.

Implementing a Manufacturing Execution System (MES) is an essential part of the optimization and modernization process of a plant. The benefits of MES cannot be exaggerated – manufacturers see massive improvement in productivity, profitability, and quality/quantity management.

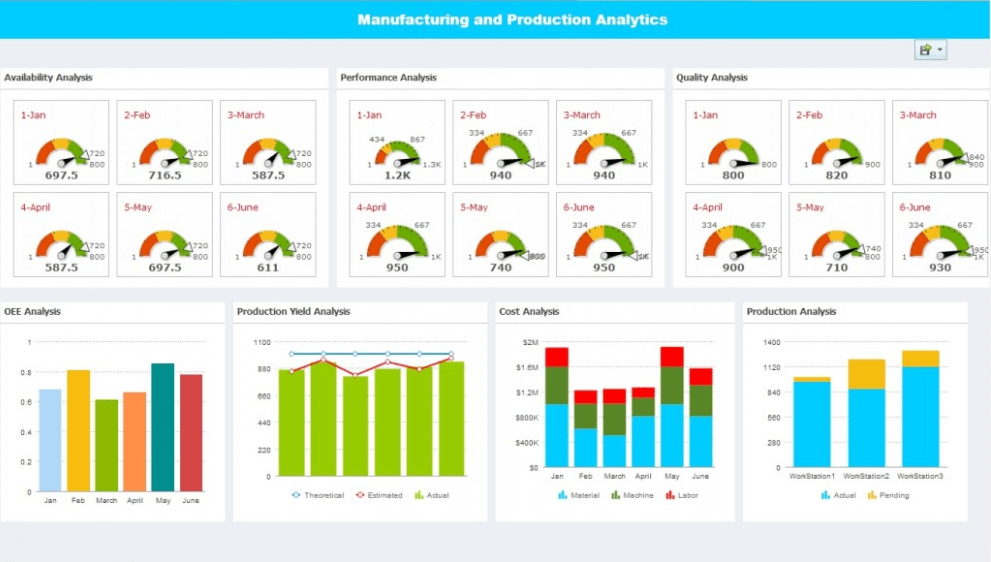

Increase Productivity and Efficiency

MES allows manufacturers to modernize and optimize the factory floor easily and efficiently. Production processes are automated by 90%, preventing issues caused by human error and increasing Overall Equipment Effectiveness by 8%. Digitizing the entire manufacturing operation allows the whole team to be literally on the same page: Sharing important data in real time, streamlining production, increasing productivity, and accelerating decision-making. Personnel are able to spend less time on trivial matters and devote more time to developing new innovations that will ensure the company’s long-term success.

Reduce Recall Risk with Track and Trace

MES solutions like PlantSharp4 Traceability monitor the ‘who, what, where and when’ of the manufacturing process. From start to shipping, MES traces which raw materials and intermediates were used as well as the workers which were on each production line. Backward tracing allows manufacturers to quickly find the origin of any problem that may arise, solving issues in near real time. Problems with machinery are also detected and fixed much faster, leading to fewer stoppages and increased output. Using data from track and trace, supervisors and operators can see if other parts of the line were affected, reducing defective products and the risk of a catastrophic recall.

Produce Golden Batches Every Time

In a perfect world, manufacturers would produce ‘Golden Batches’ every single time. However, since multiple factors – temperature inside and outside the factory, the origin of raw ingredients, etc. – change from batch to batch, the quality of the final products also differs. This lack of uniformity leads to costly material loss, faulty batches, and catastrophic product recalls.

However Machine Learning and AI are working together to bring us closer to that perfect world and desired Golden Batch. PlantSharp4 Prediction, for example, can solve this issue by taking all the elements that can change during the production process for each specific manufacturer, inputting that data into a unique algorithm, and implementing it directly on the factory floor. The algorithm then predicts if batches will be golden or problems will arise, allowing them to be immediately remedied and increasing the amount of high quality, sellable end products produced.

Implementing MES Has Never Been Easier

Implementing MES in the past required a lengthy process, requiring onsite implementation and an astronomical budget. Thankfully this is no longer the case and the world of MES has been made possible for small and mid sized manufacturers. Developers can now deliver their MES software modules through the cloud to clients around the world.

Some modules like PlantSharp4 Designer are taking customization to new heights. Now manufacturers have the option to customize their MES package directly on their own or by requesting developers to make changes over the Cloud – and unlike the past, manufacturers who customize their MES can still benefit from new software versions and updates. This cost-effective and efficient suite allows every manufacturer — regardless of location, size or budget — to implement and benefit from MES.

Interested to learn more? Contact us!

Increase Productivity and Efficiency

MES allows manufacturers to modernize and optimize the factory floor easily and efficiently. Production processes are automated by 90%, preventing issues caused by human error and increasing Overall Equipment Effectiveness by 8%. Digitizing the entire manufacturing operation allows the whole team to be literally on the same page: Sharing important data in real time, streamlining production, increasing productivity, and accelerating decision-making. Personnel are able to spend less time on trivial matters and devote more time to developing new innovations that will ensure the company’s long-term success.

Reduce Recall Risk with Track and Trace

MES solutions like PlantSharp4 Traceability monitor the ‘who, what, where and when’ of the manufacturing process. From start to shipping, MES traces which raw materials and intermediates were used as well as the workers which were on each production line. Backward tracing allows manufacturers to quickly find the origin of any problem that may arise, solving issues in near real time. Problems with machinery are also detected and fixed much faster, leading to fewer stoppages and increased output. Using data from track and trace, supervisors and operators can see if other parts of the line were affected, reducing defective products and the risk of a catastrophic recall.

Produce Golden Batches Every Time

In a perfect world, manufacturers would produce ‘Golden Batches’ every single time. However, since multiple factors – temperature inside and outside the factory, the origin of raw ingredients, etc. – change from batch to batch, the quality of the final products also differs. This lack of uniformity leads to costly material loss, faulty batches, and catastrophic product recalls.

However Machine Learning and AI are working together to bring us closer to that perfect world and desired Golden Batch. PlantSharp4 Prediction, for example, can solve this issue by taking all the elements that can change during the production process for each specific manufacturer, inputting that data into a unique algorithm, and implementing it directly on the factory floor. The algorithm then predicts if batches will be golden or problems will arise, allowing them to be immediately remedied and increasing the amount of high quality, sellable end products produced.

Implementing MES Has Never Been Easier

Implementing MES in the past required a lengthy process, requiring onsite implementation and an astronomical budget. Thankfully this is no longer the case and the world of MES has been made possible for small and mid sized manufacturers. Developers can now deliver their MES software modules through the cloud to clients around the world.

Some modules like PlantSharp4 Designer are taking customization to new heights. Now manufacturers have the option to customize their MES package directly on their own or by requesting developers to make changes over the Cloud – and unlike the past, manufacturers who customize their MES can still benefit from new software versions and updates. This cost-effective and efficient suite allows every manufacturer — regardless of location, size or budget — to implement and benefit from MES.

Interested to learn more? Contact us!

Increase Productivity and Efficiency

MES allows manufacturers to modernize and optimize the factory floor easily and efficiently. Production processes are automated by 90%, preventing issues caused by human error and increasing Overall Equipment Effectiveness by 8%. Digitizing the entire manufacturing operation allows the whole team to be literally on the same page: Sharing important data in real time, streamlining production, increasing productivity, and accelerating decision-making. Personnel are able to spend less time on trivial matters and devote more time to developing new innovations that will ensure the company’s long-term success.

Reduce Recall Risk with Track and Trace

MES solutions like PlantSharp4 Traceability monitor the ‘who, what, where and when’ of the manufacturing process. From start to shipping, MES traces which raw materials and intermediates were used as well as the workers which were on each production line. Backward tracing allows manufacturers to quickly find the origin of any problem that may arise, solving issues in near real time. Problems with machinery are also detected and fixed much faster, leading to fewer stoppages and increased output. Using data from track and trace, supervisors and operators can see if other parts of the line were affected, reducing defective products and the risk of a catastrophic recall.

Produce Golden Batches Every Time

In a perfect world, manufacturers would produce ‘Golden Batches’ every single time. However, since multiple factors – temperature inside and outside the factory, the origin of raw ingredients, etc. – change from batch to batch, the quality of the final products also differs. This lack of uniformity leads to costly material loss, faulty batches, and catastrophic product recalls.

However Machine Learning and AI are working together to bring us closer to that perfect world and desired Golden Batch. PlantSharp4 Prediction, for example, can solve this issue by taking all the elements that can change during the production process for each specific manufacturer, inputting that data into a unique algorithm, and implementing it directly on the factory floor. The algorithm then predicts if batches will be golden or problems will arise, allowing them to be immediately remedied and increasing the amount of high quality, sellable end products produced.

Implementing MES Has Never Been Easier

Implementing MES in the past required a lengthy process, requiring onsite implementation and an astronomical budget. Thankfully this is no longer the case and the world of MES has been made possible for small and mid sized manufacturers. Developers can now deliver their MES software modules through the cloud to clients around the world.

Some modules like PlantSharp4 Designer are taking customization to new heights. Now manufacturers have the option to customize their MES package directly on their own or by requesting developers to make changes over the Cloud – and unlike the past, manufacturers who customize their MES can still benefit from new software versions and updates. This cost-effective and efficient suite allows every manufacturer — regardless of location, size or budget — to implement and benefit from MES.

Interested to learn more? Contact us!

Increase Productivity and Efficiency

MES allows manufacturers to modernize and optimize the factory floor easily and efficiently. Production processes are automated by 90%, preventing issues caused by human error and increasing Overall Equipment Effectiveness by 8%. Digitizing the entire manufacturing operation allows the whole team to be literally on the same page: Sharing important data in real time, streamlining production, increasing productivity, and accelerating decision-making. Personnel are able to spend less time on trivial matters and devote more time to developing new innovations that will ensure the company’s long-term success.

Reduce Recall Risk with Track and Trace

MES solutions like PlantSharp4 Traceability monitor the ‘who, what, where and when’ of the manufacturing process. From start to shipping, MES traces which raw materials and intermediates were used as well as the workers which were on each production line. Backward tracing allows manufacturers to quickly find the origin of any problem that may arise, solving issues in near real time. Problems with machinery are also detected and fixed much faster, leading to fewer stoppages and increased output. Using data from track and trace, supervisors and operators can see if other parts of the line were affected, reducing defective products and the risk of a catastrophic recall.

Produce Golden Batches Every Time

In a perfect world, manufacturers would produce ‘Golden Batches’ every single time. However, since multiple factors – temperature inside and outside the factory, the origin of raw ingredients, etc. – change from batch to batch, the quality of the final products also differs. This lack of uniformity leads to costly material loss, faulty batches, and catastrophic product recalls.

However Machine Learning and AI are working together to bring us closer to that perfect world and desired Golden Batch. PlantSharp4 Prediction, for example, can solve this issue by taking all the elements that can change during the production process for each specific manufacturer, inputting that data into a unique algorithm, and implementing it directly on the factory floor. The algorithm then predicts if batches will be golden or problems will arise, allowing them to be immediately remedied and increasing the amount of high quality, sellable end products produced.

Implementing MES Has Never Been Easier

Implementing MES in the past required a lengthy process, requiring onsite implementation and an astronomical budget. Thankfully this is no longer the case and the world of MES has been made possible for small and mid sized manufacturers. Developers can now deliver their MES software modules through the cloud to clients around the world.

Some modules like PlantSharp4 Designer are taking customization to new heights. Now manufacturers have the option to customize their MES package directly on their own or by requesting developers to make changes over the Cloud – and unlike the past, manufacturers who customize their MES can still benefit from new software versions and updates. This cost-effective and efficient suite allows every manufacturer — regardless of location, size or budget — to implement and benefit from MES.

Interested to learn more? Contact us!

Tagged iiot, industry4, MES, Smart Manufacturing, Trunovate