Food and Beverage Manufacturing

PlantSharp MES - True Revolution by Trunovate

In the Food and Beverage Industry, maintaining high standards of quality, efficiency, and compliance is essential. Whether managing dairies, coffee production, snacks & sweets, bakeries, wineries, or soft drinks manufacturing, these factories face unique challenges that demand advanced technological solutions. PlantSharp Manufacturing Execution System (MES) provides an integrated platform to optimize production processes, ensure product quality, and enhance overall operational efficiency.

Dairies

Coffee Production

Wineries

Snacks & Sweets

Bakeries

Soft Drinks

PlantSharp MES

With PlantSharp you can track and manage the production processes:

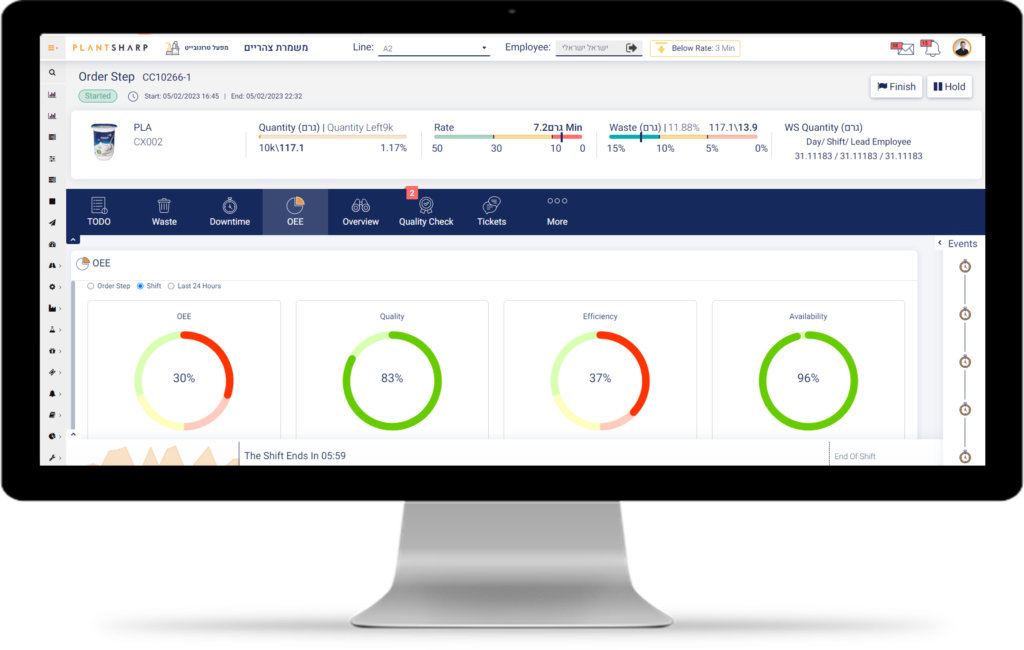

- Track manufacturing OEE, get insights and learn how to efficient the production.

- Placement of Working Orders & Shifts

- Manage the tools, the work instructions and see the HR qualifications.

- Get alerts when problems occur in the production process such as downtime and increase of waste

- Track traceability of raw materials through the production process.

PlantSharp Key Values

Regulations

PlantSharp stands with ESG and promotes sustainability, we are also certified with FDA, ISO 9001, and ISO 27001 regulations.

Easy Setup

We simplify the on-boarding setup process to allow every user the ability for self-service and quick go to live MES.

PLC Connectivity

PlantSharp works with any PLC, using Modbus protocol and internal network. There is no need to buy new equipment.

ERP API

PlantSharp provides an API for ERP interface that will integrate and synchronize the production process with any ERP.

Private Cloud

Each customer gets a private secured cloud with PlantSharp, that provides scalable infrastructure, specific customization, and extension options.

Mobile App

To complete the user interface experience, you can download PlantSharp Mobile App that will reflect the production information online. and allow you to manage the shop floor from any place.

Dashboard & Report Designer

Using the Designer, you have the flexibility to create or modify any dashboard & report that will provide you with insights and help you to track and manage your shop floor.

Security

Your safety is our top priority. Therefore, we use a secure cloud for your account and offer safe connection to the shop floor production lines and PLCs.

Compatibility to Industries

PlantSharp is suitable for a variety of industries such as: Food & Beverage, Medical, Pharma, Raw Materials: Plastics, Metal, etc., packaging, Electronics and Army.

PlantSharp Recommended Add-Ons

Quality Add-On to Monitor and manage the Quality assurance process

Maintenance Add-On to manage corrective and preventive Maintenance

Weighing Edge Add-On to integrate Weighing process into the MES

Enerweb Billing you can to monitor Energy consumption during production

PlantFlow PdM Add-On for Prediction of Downtimes using AI & ML

WIP Add-On enables you can track and manage in-process Inventory

Be Productive with PlantSharp

Request our Free Trial version and learn how to make your shop floor more efficient.